Learn more about our commitments and goals

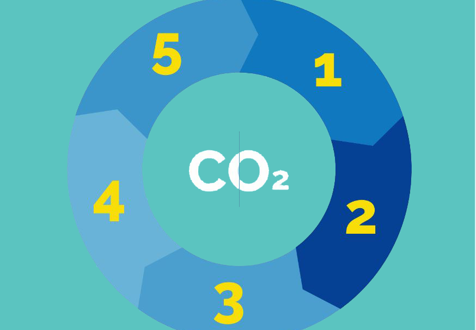

By 2030: 55% reduction in total CO2 emissions compared to 2019 baseline

Our climate and energy footprint

We aim to reduce our total CO2 emissions by 55% by 2030, compared to the 2019 baseline.

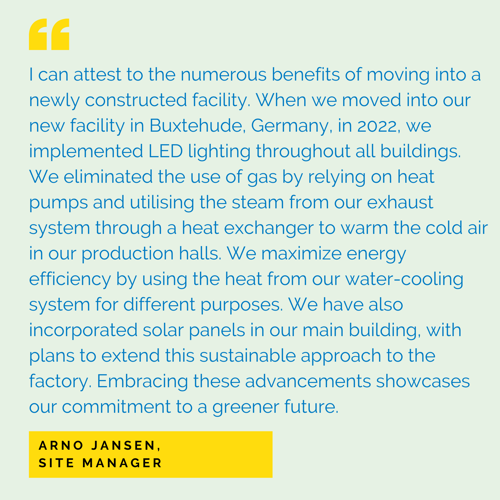

Simple yet impactful actions like turning off lights to investing in solar panels and other green-energy sources help reduce our carbon footprint. We also prioritize energy-efficient machinery when making equipment choices and have entered into strategic energy agreements that align with our sustainability goals.

By 2025: 100% of local sites will have certified environmental systems with local waste and water reduction programmes

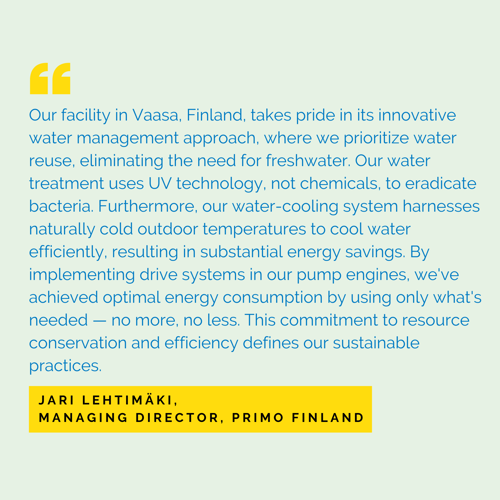

Our waste and water footprint

We're committed to ensuring that 100% of our local sites have certified environmental systems with local waste and water reduction programmes by 2025.

Our efforts are guided by the ISO 14001 standard, which provides a framework for establishing an effective environmental management system. We're also enhancing our responsible sourcing practices.

By integrating waste and water management into our sustainability approach, we aim to achieve a comprehensive and impactful reduction in our environmental impact.

Our waste and water management strategy involves implementing initiatives from Operation Clean Sweep.

Minimizing waste throughout our supply chain is also crucial. We're doing this by following the waste reduction plans in each of our factories — sorting and recycling materials such as cardboard, wood, and metal.

By 2025: 100% reuse of all raw material plastic waste from production

Our raw material footprint

We're aiming to reuse 100% of all raw material plastic waste from production by 2025.

Valuable resources are reused, not wasted. Maximizing the use of valuable resources minimizes their waste throughout our operations.

Customised programs enhance the sorting and handling of scrap at our factories. It's then distributed to our other factories for reuse. This creates a more efficient production process, in line with our sustainability goals.

Technology investment is key, too. Material separation technology means we can separate material types from co-extruded profiles. This again increases our ability to reuse our own production scrap significantly. Granulation and dosing technology allow us to process and dose scrap accurately in production.

Insights

Our people are dedicated to finding solutions to every challenge. That spirit makes for some great stories.

View all news & articles

Do you want to know more about our specific goals for sustainability?

Jaakko Salo

Group Commercial DirectorJaakko Salo is the group's head of sales, with a broad understanding of the different markets and industries. He is also our specialist in linear lighting profiles, busbars, and diffusers: As an experienced expert in the field, Jaakko's many years of experience and contributions show his deep comprehension of the possibilities of the linear lighting landscape. He's committed to innovation in his work and has collaborated with architects, designers, and industry partners to create lighting profiles that go beyond mere functionality. Jaakko can help you shape your success and light the way for the industry.